Fluoropolymer materials are prized for their chemical non-reactivity, durable design, and resistance to heat and electricity, making them a wonderful material for medical equipment such as microtubing, IV catheters, endoscopy tubes, and cardiological devices. Yet, no material is perfect and tube manufacturers must maintain proper safety procedures when casting this material.

Since fluoropolymers can withstand such high temperatures, medical tubing manufacturers must take precautions to maintain workplace safety standards. Let’s quickly explore some of the ways that shell and tube heat exchanger manufacturers protect their employees and prevent accidents on the job.

Many Components are Made of Non-Corrosive Metal

During production, medical tubing is cast from a molten resin material that cools into a fluoropolymer. Any component that comes into contact with this material must be made from a non-corrosive metal material. Typically, manufacturers use a blend of nickel and tungsten carbide to prevent the metal from leaching into the fluoropolymer tubing.

If metal were to leak into the tubing, it could lead to allergic reactions and harmful side effects. Therefore, manufacturers take extra care to maintain quality control processes and protect patients.

Casting Barrels Must Be Rated for Extreme Temperatures

Fluoropolymers are widely used across many industries for their resistance to extreme temperatures. Although useful, this means that manufacturers must heat the materials to a blazing temperature to cast them into the shape of a tube. For example, PFA must be heated to around 580 degrees Fahrenheit before it’s poured into a casting barrel. The barrel is then heated to around 740 degrees.

In order for the barrels to not melt under such extreme conditions, medical tubing manufacturers must use barrels rated to perform at temperatures up to 900 degrees Fahrenheit. They are also required to use barrels with a dual layer to help protect operators from burning themselves.

Manufacturers Use Larger Drawdowns to Prevent Melt Fracturing

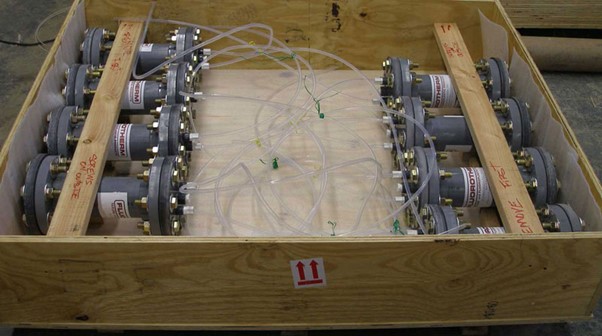

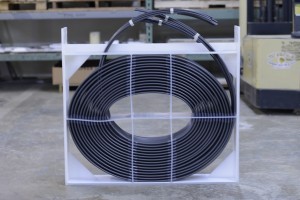

Once the fluoropolymer material has been cast into a tube shape, it’s time to cool and solidify the product. The cooling process is known as drawdown, which pulls the still-hot tubing through a series of rollers that help it maintain its cylindrical shape.

If the tubing isn’t cooled evenly or quickly enough, however, melt fracture can occur. This happens when there are areas of stress within the material that cause it to break apart prematurely or create a shark-skin texture. To prevent this from happening during production, manufacturers use larger diameter drawdowns.

Extensive Exhaust Systems Help Ventilate Toxic Fumes Away from the Production Line

When fluoropolymer materials are heated to such high temperatures, they release harmful fumes into the air. If these fumes were to linger in the production area, it could lead to serious respiratory problems for employees.

To prevent this from happening, manufacturers have installed extensive exhaust systems that remove toxic fumes away from the production line and ventilate them through an extraction hood to eliminate toxic compounds.

Final Thoughts

While medical tubing made from fluoropolymers is safe for patients, precautions must be taken during manufacturing to ensure employee safety. By following proper procedures and using state-of-the-art equipment, tube manufacturers can produce a high-quality product while keeping their workers safe on the job.