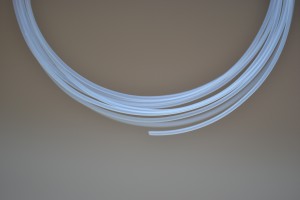

ETFE Tubing

ETFE is a fluoropolymer that is chemically and structurally similar to polyolefins such as polyethylene, thus providing a higher abrasion, impact, and crush resistance than its fully fluorinated (perfluoropolymer) counterparts -PTFE, FEP, and PFA.

ETFE is a fluoropolymer that is chemically and structurally similar to polyolefins such as polyethylene, thus providing a higher abrasion, impact, and crush resistance than its fully fluorinated (perfluoropolymer) counterparts -PTFE, FEP, and PFA.

ETFE tubing is commonly used in wiring harnesses, in exterior film applications where weathering resistance is desirable, and as a liner in tanks where specific chemical and wear resistance is required. Its high tensile strength at 25 C also leads to a higher working pressure at that temperature. ETFE’s mechanical and chemical properties were (and still are) so strong that it was chosen as a material for the Olympics! The Beijing National Aquatic Centre, built for the 2008 Summer Olympics, is the largest building made of ETFE laminate film.

Key Properties

- High abrasion and wear resistance while maintaining chemical inertness

- Higher tensile strength and working pressure than PTFE, FEP, PFA at 25 degrees Celsius

- More limited chemical resistance than PTFE, FEP and PFA

- Great for mechanical, electrical, architectural, and aerospace applications

- Maximum use temperature of 300 F (~150 C)

- Natural ETFE is semi-transparent

- More information in Technical Resources

ETFE (Ethylene Tetrafluoroethylene) tubing is known for its exceptional properties, making it suitable for a wide range of applications across various industries. Here's an expanded look at the features, applications, and industries that commonly utilize ETFE tubing:

Features of ETFE Tubing:

- Chemical Resistance: ETFE tubing exhibits excellent resistance to a wide range of chemicals, including acids, bases, solvents, and corrosive substances. This makes it an ideal choice for applications involving aggressive chemical environments.

- High Temperature Stability: ETFE tubing can withstand elevated temperatures without sacrificing its mechanical properties. It retains its structural integrity and dimensional stability even at temperatures exceeding 150°C (302°F), making it suitable for high-temperature applications.

- Mechanical Strength: Despite its lightweight nature, ETFE tubing boasts impressive mechanical strength and toughness. It can endure mechanical stresses, including bending, flexing, and impact, without undergoing deformation or failure.

- Transparency: ETFE tubing offers excellent optical clarity, allowing for visual inspection of fluids and processes. Its transparency enables operators to monitor flow, detect contaminants, and ensure proper functioning in various applications.

- UV Resistance: ETFE tubing is inherently resistant to ultraviolet (UV) radiation, making it suitable for outdoor applications exposed to sunlight. It does not degrade or become brittle upon prolonged exposure to UV rays, ensuring long-term durability and performance.

Who’s Using ETFE?

- Aerospace and Defense

- Automotive

- Chemical Processing

- Electronics and Electrical Engineering

- Renewable Energy (Solar)

Applications of ETFE Tubing:

Aerospace and Aviation

ETFE tubing is commonly used in aerospace and aviation applications, including aircraft fluid systems, fuel lines, pneumatic controls, and wiring harnesses. Its lightweight construction, chemical resistance, and temperature stability make it well-suited for demanding aerospace environments.

Automotive Industry

ETFE finds applications in the automotive industry for fuel lines, brake systems, electrical wiring, and sensor cables. Its resistance to automotive fluids, such as gasoline, oil, and coolant, coupled with its temperature stability, makes it an excellent choice for automotive components.

Chemical Processing

ETFE tubing is extensively utilized in chemical processing plants for transporting corrosive chemicals, acids, and solvents. Its superior chemical resistance ensures safe and reliable fluid handling, minimizing the risk of contamination and corrosion in industrial processes.

Electronics and Electrical Engineering

This tubing is employed in electronics and electrical engineering for wire insulation, cable jackets, and electrical conduit systems. Its high dielectric strength, thermal stability, and flame resistance make it suitable for electrical applications requiring reliability and durability.

Renewable Energy

ETFE is used in renewable energy applications, particularly in solar panel manufacturing and photovoltaic systems. It serves as encapsulation material for solar cells, providing protection against environmental factors while allowing for efficient light transmission.

ETFE tubing offers a unique combination of chemical resistance, temperature stability, mechanical strength, transparency, and UV resistance, making it an ideal choice for a wide range of. Its versatility and exceptional properties make it a preferred material for demanding environments where reliability, performance, and durability are paramount.

*Manufactured in the USA by experienced fluoropolymer manufacturer Fluorotherm™, ETFE tubing is semi-transparent in color and gamma, steam, gas, or chemically sterilizable.