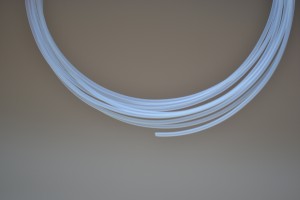

PTFE Tubing

PTFE is the classic, original, and gold standard of fluoropolymer tubing. PTFE was the "miracle" fluoropolymer invented in the 1940's by DuPont - a product originally without a market and hard to process. Most other materials continue to use PTFE as a reference for chemical resistance.

PTFE is the classic, original, and gold standard of fluoropolymer tubing. PTFE was the "miracle" fluoropolymer invented in the 1940's by DuPont - a product originally without a market and hard to process. Most other materials continue to use PTFE as a reference for chemical resistance.

The unique properties of PTFE tubing cover an impressive range. These include high use temperature compared to other polymers, almost universal chemical resistance, excellent electrical properties at high voltage and high signal frequencies, non-stick characteristics, usefulness under extreme low temperatures (cryogenic conditions), and UV resistance. However, mechanical strength and wear resistance are not criteria for which PTFE is recommended, which is one reason for the development of FEP tubing, PFA tubing and ETFE tubing.

PTFE tubing's high viscosity in the gel state (it does not truly melt) prevents it from being processed conventionally in extruders or injection molding. PTFE tubing is therefore dry molded or extruded in hydraulic extruders with (paste extrusion) or without (ram extrusion) lubricants. Paste extrusion of PTFE yields flexible tubing. However, it occurs in a batch process and thus long continuous lengths are limited to the batch size, unlike the melt-processible fluoropolymers FEP, PFA and ETFE.

Key Properties:

- The original Teflon(R) fluoropolymer

- The gold standard for inertness to the largest range of chemicals

- Lowest coefficient of friction of any polymer

- Great in a wide range of applications from electrical wire insulators, fluid flow tubing, medical devices, automotive, and hot and cryogenic (-320 F) uses.

- Excellent electrical properties - breakdown voltage and dielectric constant

- High use temperature range of 500 degrees F (260 degrees C)

- Excellent UV resistance and weatherability

- More information in Technical Resources

*Manufactured by Fluorotherm™ in the USA, PTFE tubing is semi-transparent in color and FDA approved. Request a quote today or call us at 1-877-777-2629 to speak with one of our experts about your specific application.