In beverage dispensing, ensuring safety and flavor consistency is critical. From craft breweries and coffee shops to soda fountains and cocktail bars, modern beverage systems depend on high-quality components to meet consumer expectations. One unsung hero in this process is hygienic tubing, particularly materials like FEP tubing. These specialized solutions play a pivotal role in maintaining the integrity, safety, and taste of beverages in an industry where even minor imperfections can impact customer satisfaction.

The Importance of Hygiene in the Beverage Industry

Hygienic tubing is essential in beverage systems for several reasons:

- Fluorinated ethylene propylene materials resist leaching or altering the flavor of the liquid passing through them.

- Non-reactive materials prevent contamination, keeping beverages safe for consumption.

- Tubing must endure temperature extremes, high-pressure systems, and frequent cleaning cycles without compromising its structure.

Whether it’s a cold brew coffee system or a beer dispenser at a stadium, the materials used must meet stringent requirements to perform consistently under various operating conditions.

Key Benefits

Chemical Resistance

One of the standout features of fluorinated ethylene propylene and similar materials is their high chemical resistance. Beverage systems often require cleaning and sanitization using harsh chemicals, and the tubing must withstand these agents without degradation. This ensures that no residues remain that could contaminate the beverage.

Temperature Tolerance

Beverage systems deal with a wide range of temperatures, from steaming hot coffee to icy cold carbonated soda. The tubing systems must handle extreme temperatures, ensuring the liquid’s quality and the system’s reliability.

Non-Reactive Properties

Fluorinated ethylene propylene tubing is non-reactive, meaning it doesn’t interact with acids, sugars, or carbonated liquids often found in beverages. This inert nature preserves the drink's flavor profile and ensures safety.

Smooth Interior Surfaces

The smooth interior of hygienic tubing minimizes the risk of bacterial buildup. This feature is particularly critical in beverage systems where cleanliness directly affects product safety and taste.

Compliance with Food-Grade Standards

Beverage dispensing materials must meet rigorous FDA, NSF, and other industry standards for food and beverage applications. Fluorinated ethylene propylene materials meet these requirements, making it a preferred choice in modern beverage systems.

Applications in Beverage Systems

Craft Breweries

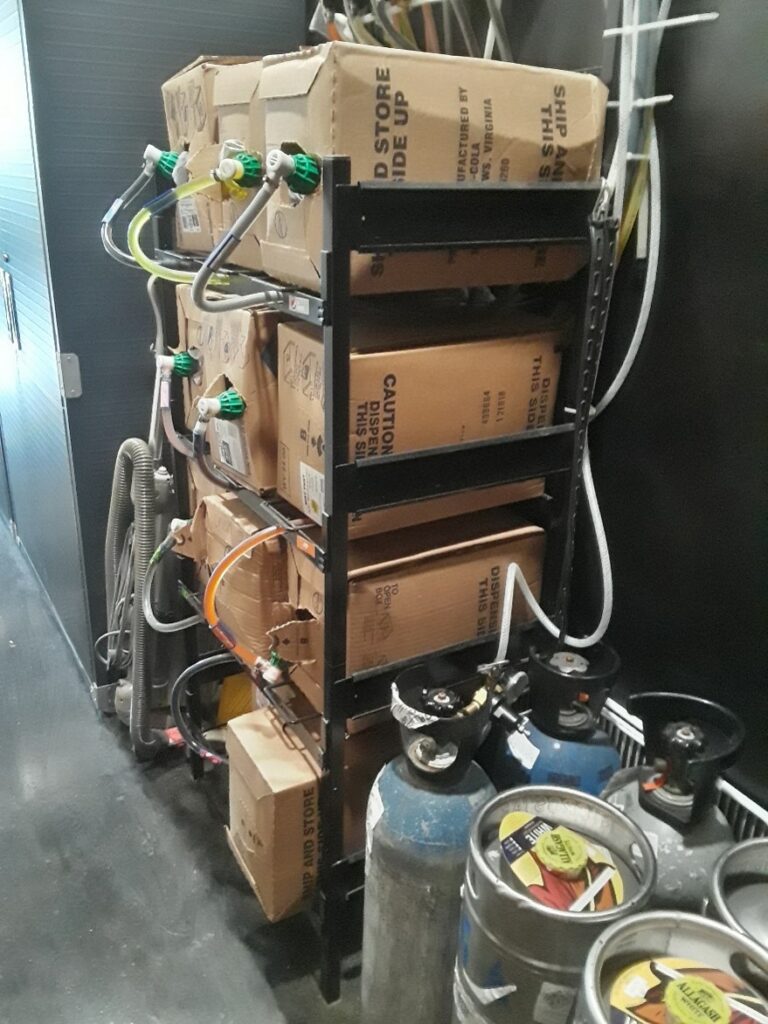

In the brewing process, maintaining the integrity of flavors is essential. Hygienic tubing is used to transfer beer during different production stages, from fermentation to packaging. Its non-reactive nature prevents unwanted flavor changes and contamination.

Soda and Soft Drink Dispensers

Soft drink dispensers rely on precise carbonation and syrup ratios. High quality materials ensure these liquids flow seamlessly without losing their intended taste, even when dispensed at high volumes.

Coffee Machines

From espresso machines to cold brew systems, coffee equipment must handle a variety of brewing temperatures and acidic liquids. It’s essential that these equipment materials maintain the flavor integrity of coffee while withstanding high temperatures and regular cleaning.

Cocktail Dispensing Systems

Bars and event venues are increasingly adopting automated cocktail systems to save time and improve consistency. The use of FEP materials ensures that alcohol and mixers maintain their intended flavors without cross-contamination between drinks.

Challenges

Despite its benefits, maintaining hygiene in beverage systems requires regular cleaning and diligent maintenance. Buildup of sugars, acids, or proteins can lead to bacterial growth if not addressed. Proper cleaning protocols are crucial, and the tubing used must be able to withstand these cleaning agents without cracking or wearing down.

Fluorinated ethylene propylene’s ability to endure rigorous cleaning processes makes it a reliable solution for beverage dispensing systems. Its non-stick properties also make it easier to clean, reducing downtime and overall maintenance costs.

The Role of Sustainability

As consumers demand more sustainable practices in the beverage industry, manufacturers are exploring eco-friendly tubing options. Fluorinated ethylene propylene tubing contributes to sustainability by being durable and long-lasting, reducing the need for frequent replacements. Additionally, its compatibility with modern cleaning systems minimizes waste from single-use materials or disposable components.

In systems designed for high efficiency, durable tubing ensures minimal waste from leaks, contamination, or failures, aligning with the industry’s push toward more sustainable practices.

The Future Outlook

Advancements in tubing technology are paving the way for even more innovative applications. For example, antimicrobial coatings and improved designs are helping beverage systems meet ever-evolving industry standards. Manufacturers are also exploring more recyclable materials and energy-efficient production methods to further align with sustainability goals.

Moreover, as automated beverage systems continue to gain popularity, the need for high-performance tubing solutions will only grow. Whether it’s a robot pouring cocktails or a self-service soda dispenser, hygienic tubing will remain a cornerstone of modern beverage technology.

Conclusion

Hygienic tubing might not be the first thing that comes to mind when you enjoy a perfectly poured beer or a refreshing soda, but it’s an essential component behind the scenes. By preserving flavor, ensuring safety, and standing up to demanding conditions, materials like fluorinated ethylene propylene are indispensable to modern beverage systems.

Hygienic tubing will continue to play a crucial role in maintaining the quality and consistency consumers expect while adapting to new challenges and sustainability goals. Whether it’s a craft brew or a classic soda, the next sip you enjoy will likely owe its perfection to the unassuming but vital role of hygienic tubing.